In the evolving landscape of manufacturing, precision engineering stands as a cornerstone of technological advancement and industrial prowess. At the heart of precision engineering lies custom part manufacturing, a field dedicated to producing components with meticulous accuracy and unparalleled quality. This article delves into the realm of precision engineering, exploring how custom part manufacturing ensures quality and accuracy, and why it is indispensable in today’s high-tech industries.

The Essence of Precision Engineering

Precision engineering is the discipline of designing and manufacturing products with exacting tolerances and intricate details. It encompasses various sectors, including aerospace, medical devices, automotive, and electronics, where the margin for error is infinitesimal. The primary goal of precision engineering is to achieve high degrees of accuracy and repeatability, ensuring that each component performs reliably and meets stringent specifications.

Custom Part Manufacturing: The Backbone of Precision

Custom part manufacturing is integral to precision engineering. Unlike mass production, which focuses on quantity, custom manufacturing emphasizes quality and specificity. This approach involves creating unique parts tailored to the exact requirements of an application, often using advanced technologies and methodologies.

Technologies Driving Custom Part Manufacturing

Several cutting-edge technologies drive the precision and quality in custom part manufacturing:

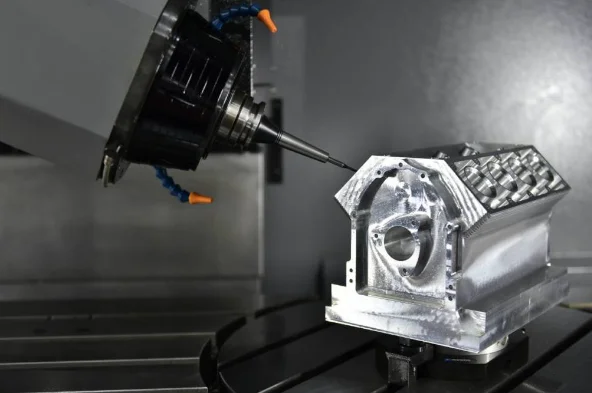

- Computer Numerical Control (CNC) Machining: CNC machines are the workhorses of custom manufacturing. These computer-controlled devices can produce parts with incredibly tight tolerances by following detailed programmed instructions. CNC machining allows for the creation of complex geometries that would be impossible with traditional manufacturing methods.

- Additive Manufacturing (3D Printing): Additive manufacturing builds parts layer by layer, offering unmatched flexibility in design. This technology is particularly useful for creating intricate and lightweight structures, making it a favorite in aerospace and medical applications.

- Laser Cutting and Engraving: Laser technology provides precise cutting and engraving capabilities. It is often used for materials that require intricate detailing and high levels of accuracy, such as in the electronics and jewelry industries.

- Electrical Discharge Machining (EDM): EDM is used to machine hard materials and create intricate shapes that are difficult to achieve with conventional cutting tools. This process involves eroding material from a workpiece using electrical discharges (sparks).

Ensuring Quality and Accuracy

Achieving high-quality and accurate custom parts involves a multifaceted approach, encompassing design, material selection, and rigorous testing.

1. Design Precision

The foundation of a high-quality custom part is a precise design, and custom part manufacturers like Danista understand this well, where engineers utilize sophisticated CAD (Computer-Aided Design) software to create detailed models and simulations of parts. These powerful tools allow for the exploration of various design iterations and the identification of potential issues before the manufacturing process even begins. This meticulous planning ensures the final product seamlessly integrates into the larger assembly, leading to superior functionality and performance

2. Material Selection

Selecting the right material is crucial for ensuring the part meets its intended function. Factors such as strength, durability, weight, and resistance to environmental conditions must be considered. Precision engineering often requires advanced materials, including specialized alloys, composites, and ceramics, which offer superior properties for specific applications.

3. Rigorous Testing and Quality Control

Quality control is an integral part of custom part manufacturing. Parts must undergo rigorous testing to ensure they meet the required specifications and performance standards. This includes dimensional inspections, material testing, and functional testing. Advanced measurement techniques, such as coordinate measuring machines (CMMs) and laser scanners, are employed to verify the accuracy of the manufactured parts.

Applications of Custom Part Manufacturing

Custom part manufacturing finds applications across a wide range of industries, each with its own set of stringent requirements.

1. Aerospace Industry

In aerospace, the demand for precision is paramount. Components such as turbine blades, structural elements, and avionics housings must be manufactured to exacting standards to ensure safety and performance. Custom manufacturing allows for the creation of parts that can withstand extreme conditions, including high temperatures and pressures.

2. Medical Devices

The medical industry relies heavily on custom parts for devices such as implants, surgical instruments, and diagnostic equipment. Precision engineering ensures that these parts are biocompatible, sterile, and function flawlessly within the human body. Customization is often necessary to cater to individual patient needs, particularly in prosthetics and dental applications.

3. Automotive Industry

In the automotive sector, precision-engineered custom parts contribute to vehicle performance, safety, and efficiency. From engine components to intricate sensor housings, these parts must meet rigorous standards to ensure reliability and longevity. Custom manufacturing allows for the integration of advanced features, such as lightweight materials and complex geometries, enhancing overall vehicle design.

4. Electronics and Semiconductor Industry

The miniaturization and complexity of electronic devices require custom parts manufactured with exceptional precision. Components such as microchips, connectors, and housings must adhere to tight tolerances to ensure proper functionality. Custom manufacturing techniques enable the production of these intricate parts, meeting the high demands of the electronics industry.

The Future of Precision Engineering

As technology continues to advance, the field of precision engineering is poised for significant growth. Innovations such as artificial intelligence, machine learning, and advanced robotics are set to revolutionize custom part manufacturing. These technologies will enable even greater levels of precision, efficiency, and customization, opening new possibilities across various industries.

Conclusion

Precision engineering, driven by the meticulous art of custom part manufacturing, is essential for the advancement of modern technology and industry. By leveraging advanced technologies and adhering to stringent quality control measures, custom manufacturing ensures that each part meets the highest standards of accuracy and performance. As industries continue to demand greater precision and customization, the role of custom part manufacturing will only become more critical, shaping the future of engineering and innovation.

Ruby Stauffer is a prominent technology blogger known for her insightful analysis and in-depth reviews of the latest tech trends and gadgets. Her blog has become a go-to resource for tech enthusiasts seeking reliable information and expert opinions on the ever-evolving world of technology.