The material choice in aerospace CNC machining is important, as the final part must withstand extreme conditions like high temperatures, pressure, and stress. Therefore, choosing the right material will improve safety and performance, as CNC machining is accurate and reliable.

Are you considering using CNC machining aerospace? This article will discuss the common materials used in aerospace CNC machining, their properties, benefits, and proper applications so you can choose the right one for your part.

What is Aerospace CNC Machining?

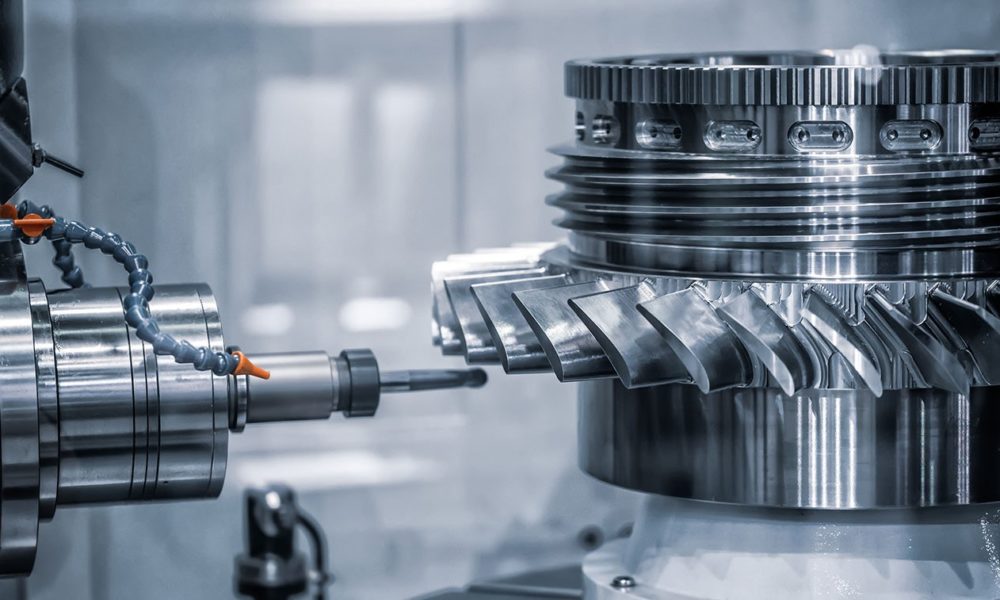

Aerospace CNC machining is the use of CNC machining to make aerospace CNC parts. The process spans many techniques, the popular ones being CNC milling, turning, and laser welding, and involves using a CNC machine to control the machining tool and produce the required part.

As a subset of CNC machining, aerospace CNC machined parts are highly accurate and consistent. As a result, the industry can achieve the safety and performance pertinent to it. The industry also relies on special types of material to further ensure safety without losing performance.

Requirements for Material Properties of Aviation Parts

Aviation parts must be made with materials that possess the following properties:

High Strength-to-Weight Ratio

Aerospace CNC materials should have a high strength-to-weight ratio, i.e., they should be light without compromising strength. This will ensure the material withstands more stress without adding minimal weight to the aircraft. It will also ensure fuel efficiency, which is an industry goal.

Heat Resistance

Aerospace CNC materials used in making aerospace parts used in the engines and exhaust of some aircraft must have high heat resistance to perform optimally at high temperatures without degrading. For example, titanium alloys can withstand temperatures exceeding 1,000°C, hence their popularity in making aerospace parts.

Corrosion Resistance

Aircraft operate in humid environments, which can lead to corrosion. As a result, the right aerospace CNC materials must be corrosion-resistant. For those without innate corrosion resistance, surface treatments that encourage these properties can be used.

Fatigue Resistance

The right CNC materials for an aerospace component should function optimally after undergoing repeated stress cycles during flight, i.e., they must have high fatigue resistance. Examples of such materials include carbon fiber-reinforced polymers (CFRP) and titanium.

Machinability

Not all aerospace parts are made using CNC machining; however, those made using aerospace CNC machining must be machinable. Common materials with high machinability include aluminum alloys and some magnesium alloys.

Common Materials for Aerospace CNC Machining

The aerospace industry relies on specific materials to ensure safety without losing performance. These materials must withstand extreme conditions like high temperatures, pressure, and stress. They include:

Aerospace CNC Machining Material 1: Titanium

Titanium and its alloys such as Ti-6Al-4V (Titanium 6-4), Ti-6Al-2Sn-4Zr-2Mo (Ti-6-2-4-2), and Ti-6Al-2Sn-4Zr-6Mo (Ti-6246) have wide aerospace applications due to their exceptional properties which include a high strength-to-weight ratio, excellent corrosion resistance, high melting point, and low thermal expansion.

Common titanium aerospace CNC machined parts include engine components, landing gear, and fasteners.

Pros

- High strength-to-weight ratio.

- Excellent corrosion resistance, especially in aerospace and marine environments.

- Good fatigue resistance.

- High-temperature stability.

Cons

- Expensive raw material and manufacturing costs.

- Difficult to weld compared to other metals.

- Limited availability of large sizes.

Aerospace CNC Machining Material 2: Aluminum

Aluminum and some of its alloys are the most common aerospace CNC machining materials with properties that include a high strength-to-weight ratio, good corrosion resistance, electrical and thermal conductivity, and excellent machinability

Aluminum’s high strength-to-weight ratio reduces overall aircraft weight, improving fuel efficiency. Furthermore, its machinability makes it easier to create complex parts with tight tolerances.

For this exact reason, custom aluminum extrusion companies utilize this material to create intricate high strength parts.

Common aluminum aerospace parts include fuselage, wings, engine components, and interior cabin structures

Pros

- Lightweight.

- Good corrosion resistance.

- Excellent machinability and formability.

- Good thermal and electrical conductivity.

Cons

- Lower strength compared to steel and titanium alloys.

- Susceptible to stress corrosion cracking in certain environments.

- Limited high-temperature capabilities.

Aerospace CNC Machining Material 3: Inconel

Inconel is a family of nickel-chromium-based superalloys known for their ability to withstand extreme environments. Aside from that, they have excellent corrosion resistance, high strength, and good fatigue resistance

Inconel’s high-temperature stability makes it suitable for parts exposed to extreme heat, such as those in jet engines. Alongside its strength, fatigue resistance and other properties, it is applicable in making parts such as turbine blades, exhaust systems, combustion chambers, and engine seals

Pros

- High strength and toughness at high temperatures.

- Excellent corrosion and oxidation resistance.

- Good fatigue resistance.

- Versatility in extreme environments.

Cons

- High cost compared to other alloys.

- Difficulty in machining and forming.

- Susceptible to embrittlement at high temperatures.

Aerospace CNC Machining Material 4: Stainless Steel

Stainless steel alloys like the 15-5 PH, 17-4 PH, and 300 series have high corrosion resistance, strength, and fatigue resistance, making them suitable for aerospace parts that need strength and corrosion resistance. Examples of such components include fasteners, landing gear, and hydraulic systems

Pros

- High strength.

- Excellent corrosion resistance.

- Good mechanical properties at both high and low temperatures.

- Ease of fabrication and maintenance.

Cons

- Relatively heavy compared to aluminum and titanium alloys.

- Higher material cost compared to carbon steel.

- Limited to moderate high-temperature capabilities compared to nickel-based alloys.

Aerospace CNC Machining Material 5: Magnesium

Magnesium alloys are among the lightest structural materials available, which is why they are popular in aerospace CNC machining. They also have good machinability and moderate corrosion resistance.

Magnesium’s high strength-to-weight ratio makes it a good material for parts that require weight reduction. Common aerospace parts made using magnesium are engine components and transmission castings.

Pros

- Lightweight with high strength-to-weight ratio.

- Excellent fatigue and corrosion resistance.

- Design flexibility and tailored properties.

- Reduced part count and assembly complexity.

Cons

- High material and manufacturing costs.

- Vulnerable to impact damage.

- Quality control challenges in production.

Aerospace CNC Machining Material 6: Carbon Fiber Reinforced Polymers

CFRP is a composite material made from carbon fibers embedded in a polymer matrix. It has a high strength-to-weight ratio, excellent fatigue resistance, corrosion resistance, and stiffness. Its exceptional strength and light weight make it suitable for making aerospace structural parts, and it is gaining popularity due to its better performance and fuel efficiency.

Common parts made using carbon fiber reinforced polymers include aircraft wings, fuselage sections, tail structures, and propellers

Pros

- Lightweight with high strength-to-weight ratio.

- Excellent fatigue and corrosion resistance.

- Design flexibility and tailored properties.

- Reduced part count and assembly complexity.

Cons

- High material and manufacturing costs.

- Vulnerable to impact damage.

- Quality control challenges in production.

Aerospace CNC Machining Material 7: Polycarbonate

Polycarbonate (PC) is a thermoplastic with high impact resistance, transparency, and lightweight properties. It is applicable in making aerospace parts that need transparency and high strength such as cockpit windows and canopies and lenses for lights and cameras

Pros

- High impact resistance.

- Lightweight.

- Optical clarity.

- Easy to mold and shape.

Cons

- Susceptible to scratching.

- It can degrade under prolonged exposure to UV radiation.

- Limited temperature resistance compared to some other plastics.

Aerospace CNC Machining Material 8: Polyetheretherketone

PEEK is a high-performance thermoplastic with excellent mechanical properties and chemical resistance. It is used to make aerospace components that require high strength and stability under extreme conditions, including seals, gaskets, and other electrical connectors and insulators.

Pros

- Excellent mechanical properties.

- High-temperature resistance.

- Chemical resistance.

- Lightweight compared to metals.

Cons

- High cost compared to other plastics.

- Difficult to process and machine.

- Not suitable for continuous exposure to high-energy radiation.

H2: Conclusion

Material choice in aerospace CNC machining is important due to the need for safety and performance. As a result, this article aims to inform aerospace part manufacturers about common materials used in aerospace CNC machining, their properties, and their pros and cons so they can make a well-informed decision.