Introduction

PCB assembly can be credited to as being one of the most significant processes in electronics manufacturing that enables printed circuit boards to be activated. In this blog, we will try to offer readers as much information as possible regarding assembly of PCB and its relevance and the stages concerned in manufacturing of operational electronics.

What is PCB Assembly?

The most common question is what is PCB assembly? It is often referred to as Printed Circuit Board Assembly is therefore the process of connecting components to a printed circuit board to form the desired electronic item. It changes a simple looking board into a more complex one, often fully functional, and can now be used in the various electronics products.

The Importance of PCB Assembly

PCB assembly plays an important role in the electronics industry due to various reasons:

- Functionality: The assembly process is that which makes a PCB useful. Without it, a PCB would just be a board with some lines that leads to the conduction of current on it.

- Miniaturisation: So assembly of circuit boards has undergone changes as the portable electronics are getting smaller in size and packed densely with more modules.

- Reliability: Right connection increases the chances that the parts are well joined enhancing the performances of the final product.

- Efficiency: Contemporary methods of PCB assembly facilitate production of large quantities of electronics products at a lower cost and in less time.

- Versatility: PCB assembly can easily be modified to accommodate several contexts depending on the device it is going to be used in whether it is consumer electronics or aerospace.

The PCB Assembly Process

The PCB assembly process involves various steps:

Design and Layout: PCB design is also done before the commencement of the assembly process which is conducted by engineers who use design software to develop the layout. This step defines the locations of parts and the paths of conductors.

- PCB Fabrication: Once the PCB layout has been designed this yields the bare printed circuit board. This is the process in which the conductive traces are formed, through a hole and then the layer of solder mask and silkscreen.

- Component Procurement: The relevant electronic parts are procured based on the bill of materials (BOM) required for assembling a Popchain. These may include resistors, capacitors, integrated circuits and connectors among others.

- Solder Paste Application: Solder paste is a semiliquid and is deposited on the regions of the PCB which is to be soldered with components. This is normally accomplished with a stencil and squeegee.

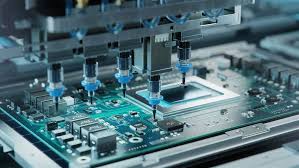

- Component Placement: Parts which include passive components and active devices or electronic components are mounted on to the PCB by using Manual insertion technique or through Robotic insertion techniques. The latter applies well, especially when a business is operating at a large scale or, indeed, implementing Lean production on a large scale.

- Reflow Soldering: To do this, the PCB is subjected to a reflow oven process, which ‘re-flow”s the solder paste into permanent construction to form interconnections between the components and the base PCB.

- Inspection and Quality Control: The practical application is further followed by visual control and automated optical control, which enables to confirm the correct positioning of components and soldering on an assembled PCB after reflow.

- Through-Hole Component Insertion: If through hole components have been used in the design they are then manually inserted onto the board at this stage.

- Wave Soldering: As for the boards equipped with through hole components, wave soldering is used to solder on the bottom side of the PCB.

- Final Inspection and Testing: Manufacturing: tin-lead, OSP and solder on paper, via-in-pad, hiddenvia, desoldering PCB assembly, and more; Inspection: optical and X-ray inspection, functional test, electrical test, etc.

Types of PCB Assembly

There are two types of PCB assembly:

Surface Mount Technology (SMT)

SMT consists in attaching the components on the surface of the PCB. It enables the components to be packed closely and hence is preferred in most contemporary electronics.

Through-Hole Technology (THT)

THT entails the passage of component leads through holes in the PCB and soldering on the other side of the board. Although THT is not frequently employed in contemporary designs, it is utilised in applications that necessitate stable mechanical fastening.

Challenges in PCB Assembly

- Miniaturisation: Due to the physical principles, as components get further miniaturised, it is very challenging to place and solder them properly.

- Heat Management: It is important that thermal regulation be managed correctly so that the soldering does not cause damage to components.

- Component Availability: However, getting certain components sometimes poses difficulties, particularly if the supply chain is collapsed.

- Quality Control: The inspection and testing methods are very crucial since it monitors consistency of quality for even more production batches.

- Environmental Concerns: New problems arise in the assembly process due to the application of lead-free solder and other environment friendly materials.

Advancements in PCB Assembly

The field of PCB assembly has made various advancements:

- Automation: The application of robotics and AI in handling assembly enhance efficiency due to the fact that they are precise.

- 3D Printing: A few PCB manufacturers are now using 3D printing for manufacturing circuit boards as well as some subsets of the devices.

- Flexible PCBs: Manufacturing methods are now being applied to flex and rigid-flex circuits expanding design options conveniently.

- Industry 4. 0: An adoption of the principles of smart manufacturing has enhanced the efficiency of assembly of PCBs while at the same time minimising errors.

- Green Manufacturing: Green products and less waste in the assembly process are among what is practised in an attempt to minimise harm to the environment.

The Future of PCB Assembly

As technology continues to advance, the future of PCB assembly is also glorifying:

- Increased Automation: This means the integration of the use of artificial intelligence and Machine Learning into the assembly processes to enhance the process.

- Nanotechnology: This principle indicates that incorporation of nanomaterials can bring about significant changes in the design as well as assembly of PCBs, and this can make it possible to develop even more miniature and effective gadgets.

- Additive Manufacturing: Some of the current trends that may be incorporated in the manufacturing process of PCB include normal 3D printing to produce prototypes within a short time and in different styles that may be required in the market.

- Sustainability: The demand for a greener industry also suggests that the employment of recyclable materials, and energy-efficient strategies will be pursued by the industry.

- Integration with IoT: PCB assembly might be designed and/or transformed to include Internet of Things (iot) within the production line.

Conclusion

Printed Circuit Board assembly also known abbreviated as PCB Assembly is a challenging and interesting process which forms the backbone of the modern electronic manufacturing industry. From smartphones, satellite communicators to many other electronic devices, well assembled PCBs are utilised. On the same note, it can be agreed that the technologies applied in PCB assembly will continue to develop to make the creation of even more advanced and integrated electronics possible. By understanding this vital step, one gets informed on how these electronics are manufactured and the need to further the innovations of this blessed field.